NUR IM APRIL 2024 UND 50 STÜCK!

Bei einer Herausforderung eines engen Freundes an einem IRONMAN-Triathlon teilzunehmen begann Markus sein Training auf seinen Sozialen Medien zu dokumentieren und baute dabei eine beachtliche Audienz auf. Sein Weg zum IRONMAN wurde zu einer inspirierenden Reise für Tausende von Menschen.

Durch seine Präsenz auf sozialen Medien begann Markus, den Schwimmsport einem breiten Publikum näherzubringen. Seine Begeisterung und Hingabe inspirierten viele dazu, ebenfalls das Wasser zu erobern und die Faszination des Schwimmens zu entdecken.

Dank der fortschrittlichen Turbinentechnologie und der intelligenten Anordnung der Strömungskanäle im Doppelboden wird eine effiziente und gleichmäßige Strömung im gesamten Pool gewährleistet.

Die 100%ige Durchströmung des Wassers über die gesamte Schwimmfläche schafft ein äußerst realistisches Schwimmerlebnis, das dem Schwimmen im offenen Wasser nahekommt.

Entwickelt in Zusammenarbeit mit einem erfahrenen Profi-Triathleten, bietet der Gegenstrompool LD Essential by MM eine erstklassige Leistung für Schwimmer aller Niveaus.

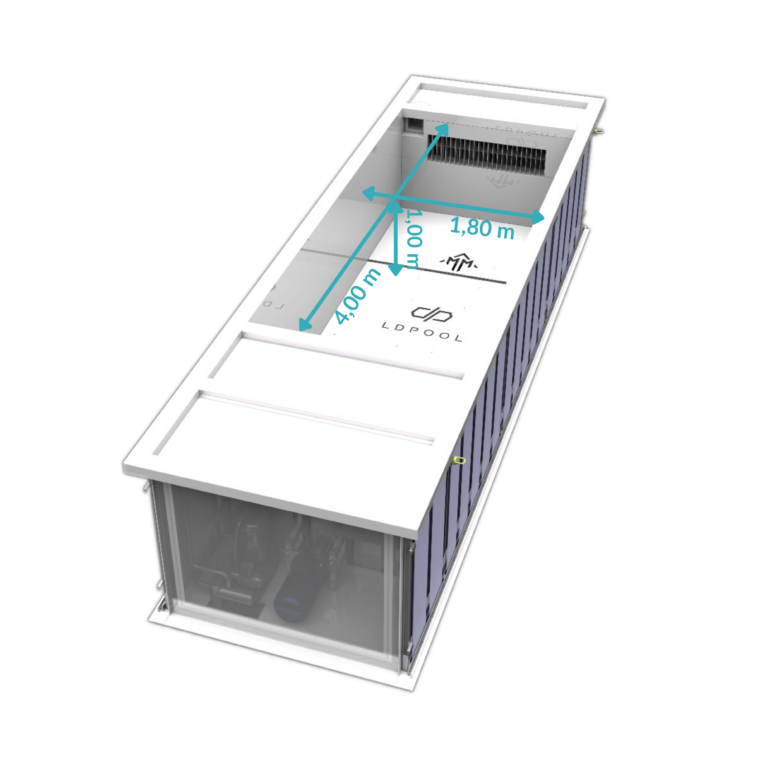

Trotz seiner leistungsstarken Funktionen benötigt der Gegenstrompool LD Essential by MM nur wenig Platz und ist daher vielseitig einsetzbar.

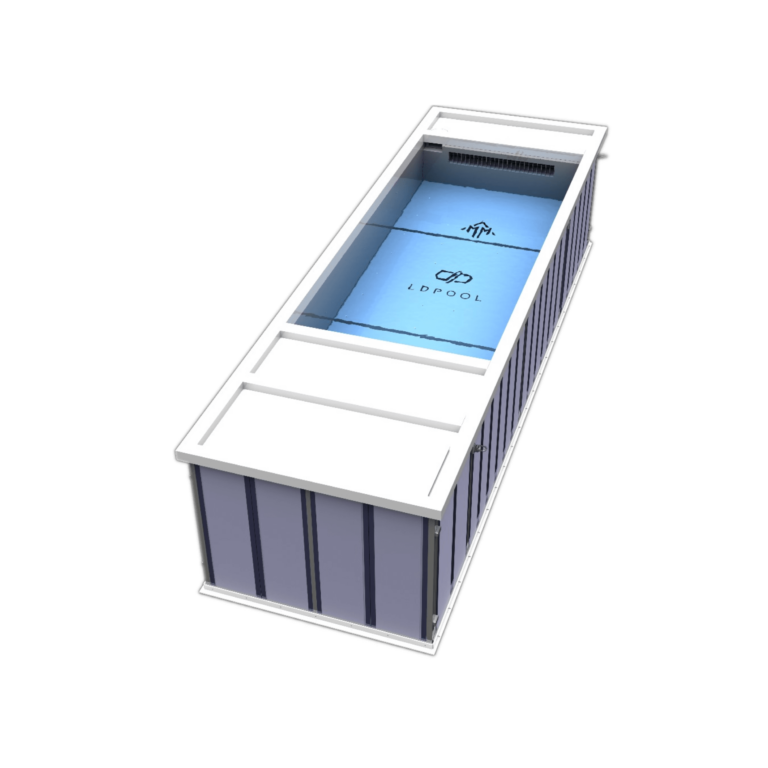

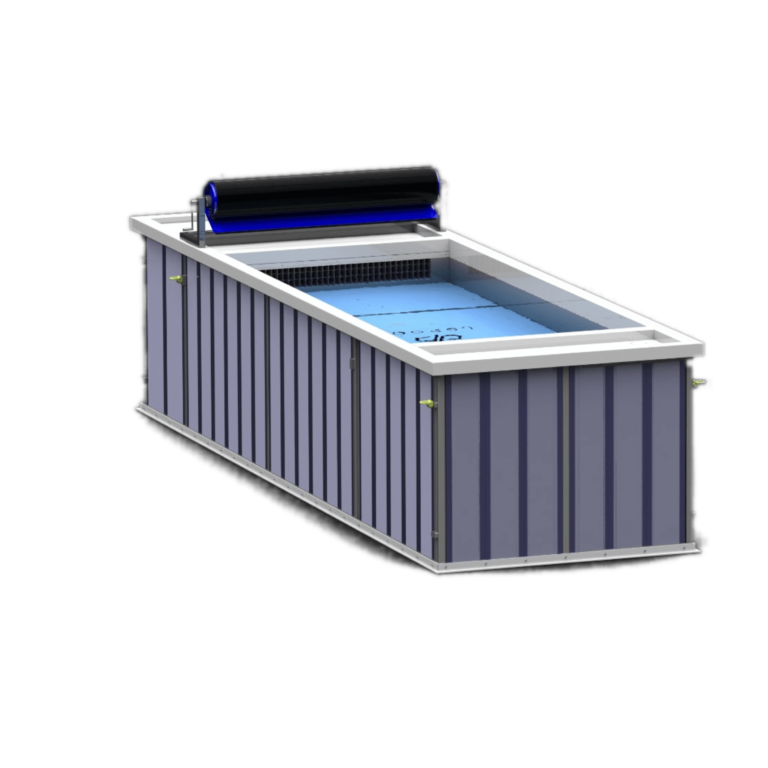

Entwickelt in Zusammenarbeit mit dem renommierten Triathlon Influencer Markus Marthaler, stellt der Gegenstrompool LD Essential by MM eine innovative Lösung für Schwimmer aller Leistungsniveaus dar. Ausgestattet mit der patentierten Strömungstechnik von LD POOL und dem Schwimm-Feedback von Markus überzeugt dieser Gegenstrompool mit einer beeindruckenden Kombination aus Leistung, Effizienz und Kompaktheit. Das Ergebnis ist ein perfektes Schwimmerlebnis für jedes Schwimmniveau.

€50.000,00 inkl. MwSt.

Wir rufen dich gerne zurück!

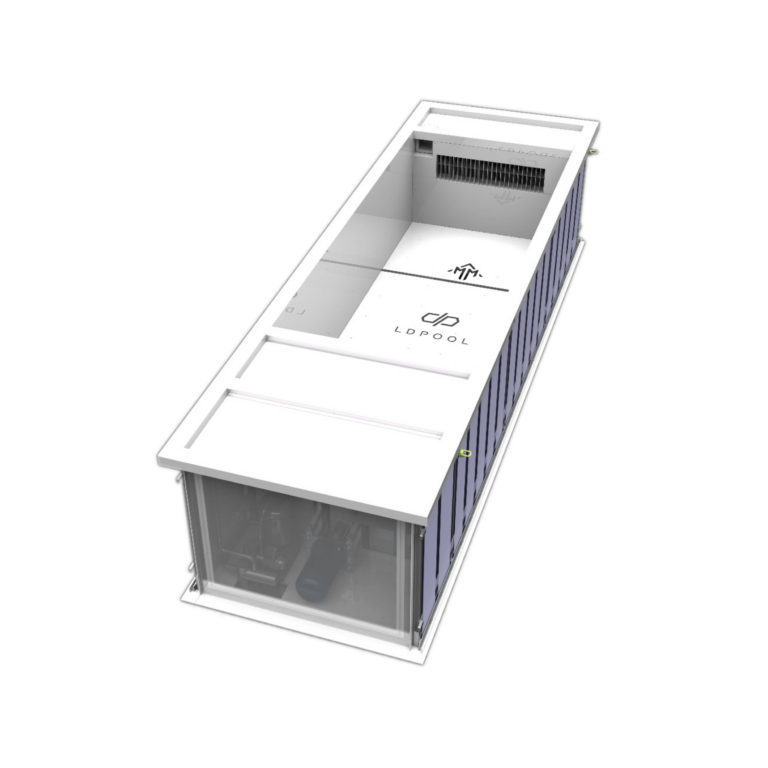

Der LD Essential by MM ist ein kompakter Fertigpool und mit der patentierten LD – Strömungstechnologie ausgestattet. Er ist als Polypropylen-Becken ausgeführt, mit einem Edelstahl Tragrahmen verstärkt und ab Werk inkl. Wasseraufbereitung voll verkabelt und verrohrt für den Einbau und Anschluss vorbereitet.

Im Technikschacht befinden sich betriebsfertig montiert und angeschlossen eine Sandfilteranlage inkl. 6 Wege Ventil und Filterpumpe sowie eine Hebepumpe.

Eine Poolheizung mit 1.5kW ist ebenfalls integriert.

Unsere wärmeisolierende Rollabdeckung ISOROL ist verbunden mit der gedämmten Poolwand und einer Bodendämmung der perfekte Schutz gegen Wärmeverlust. Die ISOROL ermöglicht auch im Winter Badegenuss wie in einer Therme.

Lade dir jetzt das Info Guide für den LD Essential by MM Gegenstrompool herunter. Hier erhältst du alle wichtigen Informationen zum Produkt, den technischen Daten, Transport, Einbau, Anschlüssen und zur Inbetriebnahme. Wir stehen dir natürlich für Fragen auch gerne zur Verfügung! Klicke einfach hier!

Copyright © 2023 LD Pool System GmbH